_small.jpg) |

|

This is the seventh collaborative clock project that Dave

and I have completed, and this one completely got away from

us. We started working together on this one in

November and over the course of nearly 300 emails finally

arrived at the design that we both liked. During the

design process of each clock we constantly reference the

"KISS principle" (Keep It Simple Stupid) - in this case,

somehow we lost sight of that basic design principle but it

all turned out okay in the end. |

|

|

|

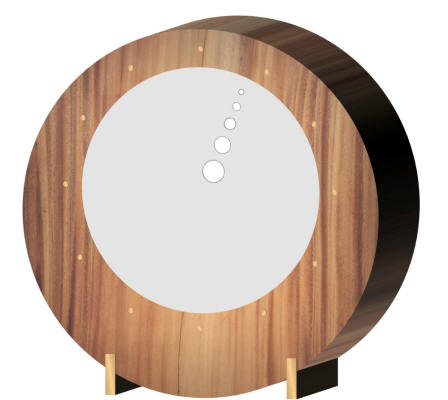

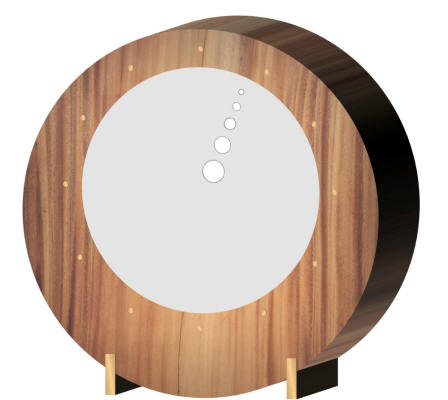

The initial concept was a small wood mantelpiece style clock

with a backlit hand of glowing dots that would show on a

screen of translucent white plastic. Brass dots would

show the hour hand positions. This was a simple and

elegant design, but Dave went off on a tangent and became

focused on the idea of a swinging back lit pendulum. In order

to get a pendulum that swung once per second, we needed a

certain length to accomplish that, and of course it needed

to be a backlit circle or line that would move back and

forth behind the screen. |

|

|

|

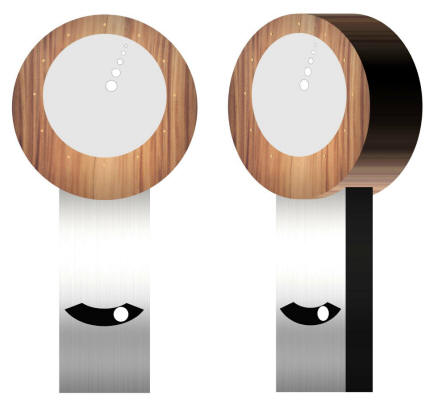

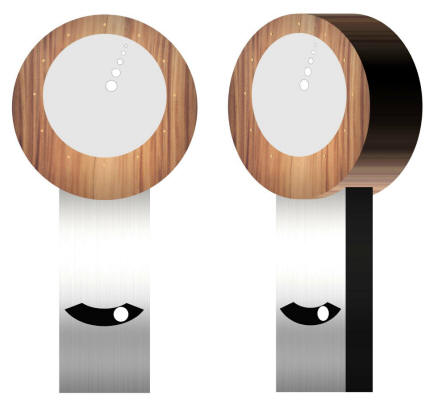

The pendulum concept drove the height of the clock to being

quite tall, and we also experimented with a smaller pendulum

above the clock face. But finally we decided we liked

the idea of a simple clock with legs in a design that

would evoke a

James

Krenov cabinet style while also being reminiscent of a

grandfather clock.

Once I saw the final rendering (above far right) that Dave did I told him that

my best friend and neighbor

John Rogers would be the perfect person to do the

woodworking since this was a bit outside the scope of my skills as a woodworker. |

|

|

|

|

John used his skills and experience as a woodworker to create a design

with good proportions that evokes the Krenov style in which the cabinet appears

to float above the legs. Shown above is the completed case, and rendered

the clock face and dots that I added later. The rendering on the right was

created after John had provided Dave with a detailed sketch of the overall

proportions and colors. |

|

|

|

It took John a little over a week to make the case from cherry and legs from

ebonized ash. John is a consummate woodworker and used traditional dovetails

and frame and panel construction. His meticulous craftsmanship shows at

every step and in every detail. The clock case is made from cherry wood,

while the legs are ebonized ash. |

_small.jpg) |

_small.jpg) |

_small.jpg) |

|

The responsibility fell to me to install the ebony dots that define the clock

hand positions. Four of the dots were larger at the 12, 3, 6, and 9

positions. It made me quite anxious to drill into John's beautiful

cabinetry and my hands were literally sweating the entire time I was working on

this but it came out okay in the end. The tapered plugs had to be precision fit

so the top surface was smooth and flush with the clock face. |

_small.jpg) |

_small.jpg) |

|

The dots were actually an idea suggested by my ex-wife

Rebekah Younger and really complete

the clock face while making it easier to read the time. |

_small.jpg) |

_small.jpg) |

|

A stepper motor drives the disc. Stepper motors are extremely

precise and can resolve 3200 steps per revolution. I machined the

shaft adapter on my metal lathe to which the clock disc will attach. |

_small.jpg) |

|

|

The clock hand is made from a disc of thin aluminum with a slot cut in it to

allow light to come through from behind. Originally, Dave and I had pictured

the hand being a series of circles ending in a short thin line, and explored

several options. But we eventually decided to simplify it down to a basic

single line. I milled the slot on my mini milling machine. |

|

|

|

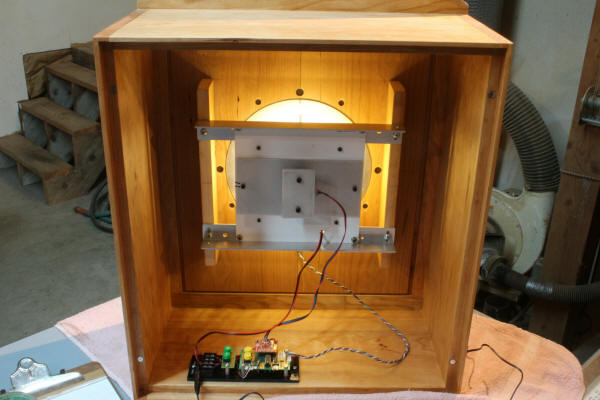

The internal clock mechanism is relatively complex. Shown above are the

clock "hand" disc and the LED back light that I constructed from 8 - 1 Watt warm

white LEDs. The whole mechanism was constructed in layers starting with

the screen, rotating clock face with hand slot, a layer of translucent acrylic

diffusion, the LED lights, and then the motor on the back. the structural

supports all have slots to allow the mechanism to be centered perfectly in the

cabinet clock face. |

_small.jpg) |

|

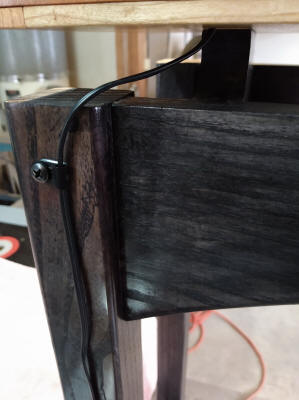

Shown above is the final electronics control system. The two green buttons

let you set the hour and minute position in five minute increments. The

two yellow buttons allow you to set the brightness in 20 discrete steps.

The whole clock operates from a small 12 V DC wall adapter and the black wire

runs down the back of one of the rear legs where it is secured with small black

clips so that it is not unsightly.

At the beginning of this project I had it in mind to embed cuckoo clock like

features. For instance every hour the backlight would change brightness by

going dim a number of times relevant to the hour. So for instance, at 6 PM

the clock hand would dim six times. We also considered a feature where you

would wave your hand in front of the clock and the hand would swing around and

stop to show the minutes position rather than the our position before reverting

back to the current time. The code for all of this became so onerous that

it became too much for me and I was no longer enjoying the process. Dave

graciously suggested that we step back and make just a simple clock. The

only embedded "feature" is that at the 12 o'clock hour, the clock hand goes

through a complete rotation to recalibrate. There is a small

sensor that detects when the hand is exactly at the 12 o'clock position in the

clock and it swings around until it finds that spot and stops. So this is

something to look forward to every noon and midnight as the hand sweeps around

once. |

_small.jpg) |

|

|

John had designed the case so that the back simply attaches magnetically making

it very easy to remove. I drilled two holes that allow for ventilation and

also they make easy handles for removing the back. |

_small.jpg) |

_small.jpg) |

|

Since Dave lives in North Carolina, and I am in Maine, I had to build some very

substantial crates in order to ship everything down to him via UPS.

Fortunately they survived intact and Lux now resides in Dave's dining room. |

_small.jpg) |

_small.jpg) |

|

The clock is 79 inches high, and in my workshop it felt quite imposing, but I am

pleased to see that with Dave's taller ceiling it blends in very nicely.

Dave and I are both very pleased with this clock as is my friend John. |

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)

_small.jpg)