This is my third collaborative project with Dave

Bruckenstein. We call this one the Light Guide Clock

due to the 1/2" acrylic rods inside that guide the light

from LEDs in the back to the clock face. The original

premise was to create a sense of magic so that people would

wonder how the light got to the face. It turns out

that the walls of the rods are more visible than we

expected, but we like the result nonetheless.

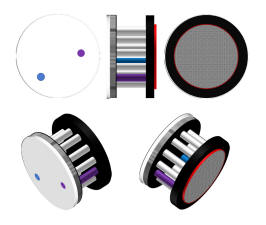

Dave likes to do CAD visualizations as the design evolves

and we explore options for materials and technology.

We started with a very basic rectangular wood base and it

evolved as we worked out the cylindrical clock "mechanism"

as a removable module. |

|

|

|

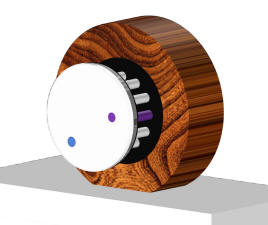

Below is the final design - we later added a clear cylinder

to keep the dust off the light guides. |

|

|

|

In the image below right - the time displayed is 8:05.

The blue dot is the hour and the red one shows the minutes

to the nearest 5, so it is not that accurate for any given

minute. What is neat is that when the hands overlap at

say 1:05 there is just one dot that shows as purple since

the colors combine. This makes reading the time a

little inscrutable which is an essential part of Dave's

concept for his clocks. |

_small.jpg) |

_small.jpg) |

| Once we had settled on the

dimensions I designed a circuit board with programmable RGB

LEDs on the front and circuitry on the back. This

design incorporates a real time clock chip with battery

backup so it can retain the correct time even if left

unplugged for weeks. There are 2 set buttons that

allow you to adjust for daylight savings time. |

_small.jpg) |

_small.jpg) |

Once that was assembled, I had to program the light

sequences and get the real time clock code working which

took way longer than anticipated due to the weird number

format used in the clock chip to represent time. (For

you geeks, it uses binary coded decimal).

My next step was to construct the cylindrical assembly.

We both gave the dimensions of the black and white material

a lot of thought. So the front has 1/8" translucent

white for the clock face, and that is backed by 1/4" black

to support the light guides and to isolate the dots of

light. The back has a 1/2" thick piece of black that

also supports the PCB and the light guides that are made of

1/2" diameter acrylic rods. There are 3 magnets that

align with 3 in the case so that the module indexes into the

correct orientation and is held in place firmly. You

need to pull the module out to set the time. |

_small.jpg) |

_small.jpg) |

|

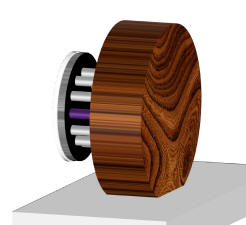

Finally I acquired a nice piece of black walnut that I cut

and glued up to get the thickness we wanted. Then I

turned it on my lathe. |

|

_small.jpg) |

| In Dave's CAD model he had

visualized the wood as a perfect cylinder. But As I

worked the wood I felt that a rounded back would look and

feel "warmer" to the touch. |

_small.jpg) |

_small.jpg) |

_small.jpg) |

_small.jpg) |

| |

|

|

|

|

|