|

October 5, 2008 |

When I converted my workshop building from an

unfinished open structure to a super insulated,

solar heated space back in 2001 I

ended up with a building that is very well sealed - perhaps too well. The building

has a combination of sprayed in isocyanurate (Corbond)

foam and fiberglass that results in R30 walls and R40 roof insulation

values. The original cheap leaky windows are sealed in the winter

with interior window insulation

panels that totally block all air movement through them. I have been

concerned about air quality due to the extreme tightness of the envelope

especially in my closed second floor office. When I converted my workshop building from an

unfinished open structure to a super insulated,

solar heated space back in 2001 I

ended up with a building that is very well sealed - perhaps too well. The building

has a combination of sprayed in isocyanurate (Corbond)

foam and fiberglass that results in R30 walls and R40 roof insulation

values. The original cheap leaky windows are sealed in the winter

with interior window insulation

panels that totally block all air movement through them. I have been

concerned about air quality due to the extreme tightness of the envelope

especially in my closed second floor office.

This year I have been gaining an education in building science that has

led me to understand that average homes need to have a minimum of 1/3 of

the building air exchanged every hour at minimum for good air quality (according

to the complex guidelines put out by ASHRAE). I learned this from Kurt Johnson of

Fresh Air

Ventilation Systems in Lewiston, Maine when he presented a very

informative lecture on ventilation systems for the

Midcoast Green Collaborative. According to Kurt: "I think it

is reasonable to consider a rate of 1 air change per hour mechanically

which would be a more likely rate that would provide optimum health and

air quality. What I would say about ASHRAE is that it is better to have

a standard of some ventilation than to have no standard. I personally

would not consider this a rate for optimum health and air quality."

Most houses leak enough that they see at least one full air exchange per

day and older houses much more (at the cost of a lot of wasted heat). So I have paid the price for sealing up

my building too well -- now I have stuffy uncirculated air that can be

unhealthy. This is particularly noticeable in my 2nd floor office with

only one (sealed) window and one interior door. The heat for this 11 by

18 foot room is a 10ft. baseboard radiator, which is occasionally

supplemented by a 1kW electric heater.

The only air that is forcibly removed from the building is drawn out by the

100CFM exhaust vent of the propane backup heater for my

solar heating

system at the far end of my building from my office. This can run from 4 to 12 or more hours a day in the dead of

winter when it is cloudy. I have wondered where the incoming air comes from.

Another issue is the poor draw of my wood stove, when the vent is

running I often get a back draft that forces me to open the door to start a

fire. Once the fire gets going I can close the door but at the

cost of a lot of heat loss and subsequent poor draft. (The

wood stove was added

as a backup to the solar/propane heating system to reduce propane usage

during extended overcast days.) |

_small.JPG)  The

solution to an overly tight envelope is to install a heat recovery unit that vents air out of the

building through a heat exchanger that transfers heat to an equal amount of fresh air

that is blown in to the building. I decided to install a

simple relatively inexpensive

Airivia

unit made by SunCourt. There are 2 100CFM blowers in

the box, with the (black) heat recovery core in the center, and

electronics on the left between the 2 fans. I spent another $100

or so on ducting and hardware, so my total cost including shipping was

around $600. But this does not count the many hours I invested in

installing this equipment. The

solution to an overly tight envelope is to install a heat recovery unit that vents air out of the

building through a heat exchanger that transfers heat to an equal amount of fresh air

that is blown in to the building. I decided to install a

simple relatively inexpensive

Airivia

unit made by SunCourt. There are 2 100CFM blowers in

the box, with the (black) heat recovery core in the center, and

electronics on the left between the 2 fans. I spent another $100

or so on ducting and hardware, so my total cost including shipping was

around $600. But this does not count the many hours I invested in

installing this equipment. |

DISCLAIMER!

The heat recovery system presented here is a budget system designed

primarily to get fresh air into my small 200sq ft office. I am

aware that as a do-it-yourselfer I may not have designed an optimal

system. I am sharing what I have done for educational purposes. I

strongly suggest that if you are interested in installing a HRV in your home

that you contact a qualified professional that can engineer a system

that is optimized for your specific needs. |

The

heat recovery core contains alternating sheets of black

Coroplast that overlap in a cross pattern that allows incoming air to pass by in close contact

to outgoing air so that the heat is transferred from one to the other

without actually mixing the air streams. Since this model claims

86% efficiency at low speed, and 82% at high speed, I will be running it

on low speed and needing a bit more heat to make up the 14% loss.

Over the last few years I have managed to reduce my

propane consumption quite

a bit, so a small increase should not be too expensive. The

heat recovery core contains alternating sheets of black

Coroplast that overlap in a cross pattern that allows incoming air to pass by in close contact

to outgoing air so that the heat is transferred from one to the other

without actually mixing the air streams. Since this model claims

86% efficiency at low speed, and 82% at high speed, I will be running it

on low speed and needing a bit more heat to make up the 14% loss.

Over the last few years I have managed to reduce my

propane consumption quite

a bit, so a small increase should not be too expensive. |

The

simple control panel has a power switch, high/low switch and a selector

switch for the defrost feature, more on that later. I checked out the

power consumption with no ducting attached and found 52 Watts on the low

setting and 68 Watts on the high. This goes up by a few Watts if I

block one of the vents. The high speed creates about 100CFM (cubic feet

per minute) air flow, and the low setting is about 70CFM according to

the specifications. The

simple control panel has a power switch, high/low switch and a selector

switch for the defrost feature, more on that later. I checked out the

power consumption with no ducting attached and found 52 Watts on the low

setting and 68 Watts on the high. This goes up by a few Watts if I

block one of the vents. The high speed creates about 100CFM (cubic feet

per minute) air flow, and the low setting is about 70CFM according to

the specifications.

Since

the HRV will be more than adequate to ensure over 9 air exchanges per

day on the low setting, I have decided to leave it on low and add my own

external timer to run it only during my work hours and leave it off most

of the night when it is coldest. The

timers that I use around the place to conserve energy come from

Harbor Freight.

They cost around $10.00 and are very well designed, with full battery

backup and multiple timing options per day. (timer as later replaced

with a light sensor-see below) Since

the HRV will be more than adequate to ensure over 9 air exchanges per

day on the low setting, I have decided to leave it on low and add my own

external timer to run it only during my work hours and leave it off most

of the night when it is coldest. The

timers that I use around the place to conserve energy come from

Harbor Freight.

They cost around $10.00 and are very well designed, with full battery

backup and multiple timing options per day. (timer as later replaced

with a light sensor-see below)

If I run the unit 6 hours/day at the 52 Watt setting that comes to 9.36

KWH per month. We are paying 15 cents/KW her in Maine,

so my monthly cost to operate the HRV will be about $1.40

But there is the extra cost to make up the lost heat to consider too, so

I will be using slightly more propane and firewood. |

I decided to add labels to the front cover that will

aid me when I educate people about its function and purpose. I am

constantly showing my solar heating system to people who are considering

adding one themselves and the HRV is installed high on the wall of

my utility room where it will be inaccessible to open easily. I

used 2 shelf brackets, and also tied it to a ceiling beam with steel

strap for safety. I decided to add labels to the front cover that will

aid me when I educate people about its function and purpose. I am

constantly showing my solar heating system to people who are considering

adding one themselves and the HRV is installed high on the wall of

my utility room where it will be inaccessible to open easily. I

used 2 shelf brackets, and also tied it to a ceiling beam with steel

strap for safety. |

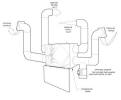

Running

the 6 inch ducts was relatively simple. I started with the duct

that feeds air into the building and ran it up to the 2nd floor and

behind the stub wall at the bottom of the roof slope to my office where it enters via a

grille behind my filing cabinets. I used flex duct to make the

initial run, then rigid galvanized 6" duct for the 14 foot run to the

office where it elbows into the room. SunCourt do not recommend

using flex duct as it creates turbulence that reduces air flow, but this

connection was rather challenging to make with regular rigid duct so I

compromised for a few feet. Running

the 6 inch ducts was relatively simple. I started with the duct

that feeds air into the building and ran it up to the 2nd floor and

behind the stub wall at the bottom of the roof slope to my office where it enters via a

grille behind my filing cabinets. I used flex duct to make the

initial run, then rigid galvanized 6" duct for the 14 foot run to the

office where it elbows into the room. SunCourt do not recommend

using flex duct as it creates turbulence that reduces air flow, but this

connection was rather challenging to make with regular rigid duct so I

compromised for a few feet. |

The

air flow from my 2nd floor office to the utility room passes through 2

doors that I leave closed, So I cut holes above each door and installed

grilles to allow air to move throughout the building unimpeded. The

air flow from my 2nd floor office to the utility room passes through 2

doors that I leave closed, So I cut holes above each door and installed

grilles to allow air to move throughout the building unimpeded. |

I found all the duct material and grills at

the nearest big box hardware store and spent about $80.00 - except for the exterior vent caps.

I had to research them on-line and order them separately since no local

retailers carry 6 inch vent caps. These caps provide weather

proofing and have a mesh cover to prevent birds from nesting inside.

For the incoming air I had to remove the back draft flapper on one unit.

I also added fine window screen to the 1/4" wire mesh bird screen to

prevent bugs from entering the vents. I found all the duct material and grills at

the nearest big box hardware store and spent about $80.00 - except for the exterior vent caps.

I had to research them on-line and order them separately since no local

retailers carry 6 inch vent caps. These caps provide weather

proofing and have a mesh cover to prevent birds from nesting inside.

For the incoming air I had to remove the back draft flapper on one unit.

I also added fine window screen to the 1/4" wire mesh bird screen to

prevent bugs from entering the vents.

|

The HRV unit has 2 options that address

defrosting the core in cold weather. The first is an internal

method, to quote the manual: "The thermostat inside the unit will

protect the unit from freezing up under very cold outside conditions.

The thermostat is pre-set at the factory to stop the operation when

fresh air to the house cannot be held above approximately 45F (7C).

When the temperature in your home is 70F (21C) the frost protection can

normally be expected to activate at an outside temperature of 0F (-18C)

or lower." Since we routinely see temperatures below 0F in

the winter. I expect that this feature will be needed.

The External method requires that a T be installed in the incoming air

duct from the outside and an electrically operated damper be installed

in the T such that when the unit enters freeze protection mode a signal

is sent to open the damper and mix house air with the external air.

This allows for an uninterrupted flow of fresh air while avoiding

freezing the unit's core. It should also allow for warmer air

circulation. The External method requires that a T be installed in the incoming air

duct from the outside and an electrically operated damper be installed

in the T such that when the unit enters freeze protection mode a signal

is sent to open the damper and mix house air with the external air.

This allows for an uninterrupted flow of fresh air while avoiding

freezing the unit's core. It should also allow for warmer air

circulation.

I ordered a damper separately

and installed it next to the HRV in the incoming cold air line.

The HRV includes a kit of parts to modify a damper to prevent it from

fully opening so that when it is activated it just opens about 20

degrees to

allow a small amount of warm air to enter the incoming airstream.

I could not find a 6" motorized damper on-line, so I got a 5" one and

adapted it using a 6" end cap. I ordered a damper separately

and installed it next to the HRV in the incoming cold air line.

The HRV includes a kit of parts to modify a damper to prevent it from

fully opening so that when it is activated it just opens about 20

degrees to

allow a small amount of warm air to enter the incoming airstream.

I could not find a 6" motorized damper on-line, so I got a 5" one and

adapted it using a 6" end cap. |

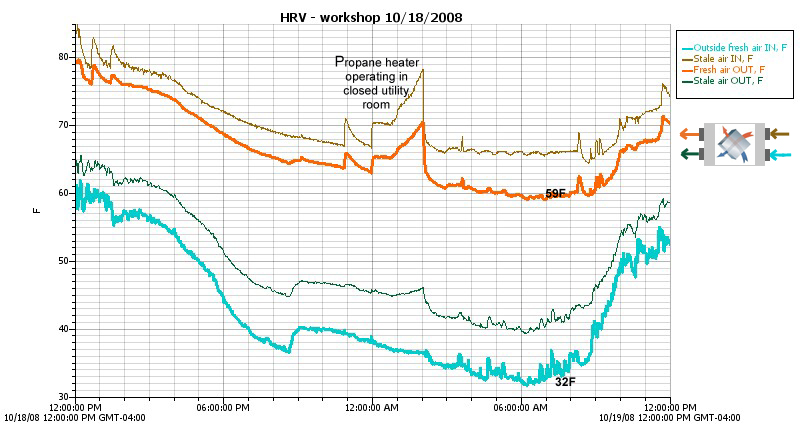

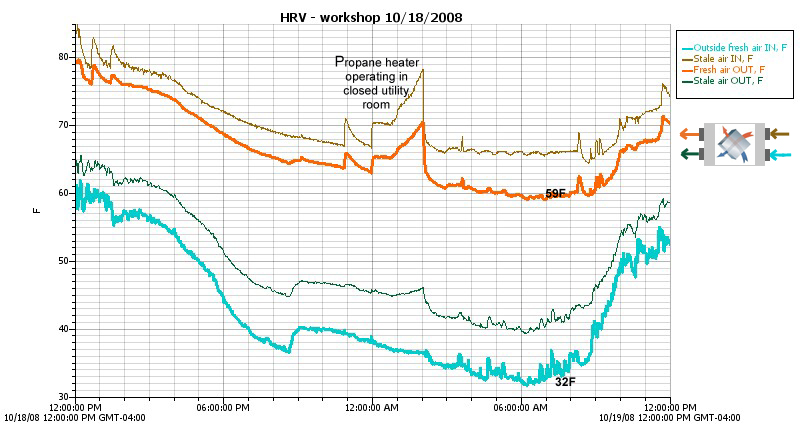

I left the HRV running on low speed and used my data logger to document a 24 hour

cycle on October 18-19, 2008 as the outside temperature dipped down to

freezing. I placed the 4 sensors right inside the unit. The

HRV output only dropped to 59F as it used the outgoing heat from the

building to raise the incoming air temperature by 27F in the

coldest part of the morning.

Based on the data I have decided to try running the HRV on half speed

(52 Watts) from 10:00am to 4:00pm - the warmest times of the day.

Running it in the dead of winter when the temperatures here in Maine

often remain below 10F at night does not seem wise! This timer

strategy will

cost me under $2.00/month at my electric rates.

|

October 2011 update - see below

Installed real-time temperature monitoring system. |

October 2014 update

When I recently installed a

single room energy recovery ventilator in the dining room of our

house, it came with a special feature that allows it to respond to

ambient light in the room and switch to its lowest speed at night when

it is dark. This got me to thinking because I find myself

adjusting the programming of the timer that switches on my HRV to

correct for changing daylight hours. It really makes sense to only

operate the HRV when it is light outside and therefore warmer.

Also, these are the hours that I am in my office. Being an

electrical engineer, I realized that I could build a device that

would turn on the HRV only when the ambient light in my utility room is

bright. The room has a south facing window so it gets sun very

early in the morning as soon as the sun rises. |

I

designed a simple circuit that uses a small photocell to detect ambient

light from the adjacent window, and wired it into a plug box with an outlet on it. The circuit switches

an internal solid-state relay to activate the outlet. For the DIY inclined this was built into an

AC Wall Plug

Enclosure made by Polycase. These nifty boxes sell for under

$5 and come with a three-prong male plug built in and a cut out for a

standard snap in three prong outlet, and there is plenty of room inside

for circuitry.

Here is the

schematic of what I built, it includes a green power indicator, red

power on indicator and an adjustment knob for setting the light level at

which the relay activates. Click the images to see larger

versions.

and wired it into a plug box with an outlet on it. The circuit switches

an internal solid-state relay to activate the outlet. For the DIY inclined this was built into an

AC Wall Plug

Enclosure made by Polycase. These nifty boxes sell for under

$5 and come with a three-prong male plug built in and a cut out for a

standard snap in three prong outlet, and there is plenty of room inside

for circuitry.

Here is the

schematic of what I built, it includes a green power indicator, red

power on indicator and an adjustment knob for setting the light level at

which the relay activates. Click the images to see larger

versions.

Now my HRV only operates from dawn to dusk automagically! |