|

My

wife's office

desk is

in the corner of our daylight basement surrounded by large windows.

She has always complained that she is cold in that corner despite the

very effective wood stove that we use to heat the entire basement that

is her studio workspace. This year I decided to do something to

make her more comfortable. The first step was to improve the

insulation factor of the windows,

click here

to learn more about the window insulation panels that I designed.

My next step was to improve the insulation of the

exposed concrete foundation

wall. I have been doing a

similar project around

the frost wall of my workshop. The inside of the basement concrete wall is

framed with 2X4s and filled with fiberglass which has an R value of

about 13. Not much when the outside ambient temperature remains

below freezing for several months a year here in Maine. My next step was to improve the insulation of the

exposed concrete foundation

wall. I have been doing a

similar project around

the frost wall of my workshop. The inside of the basement concrete wall is

framed with 2X4s and filled with fiberglass which has an R value of

about 13. Not much when the outside ambient temperature remains

below freezing for several months a year here in Maine.

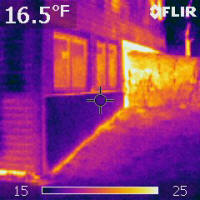

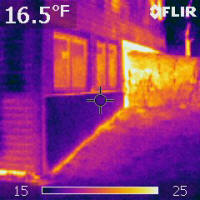

The exposed un-insulated wall is shown at left. |

So

I decided to add 4 inches of rigid foam insulation to the exterior of

the wall for an insulation rating of about R24. First I dug down

about 8 to 12 inches and 5-6 inches away from the wall. Then

I attached 2 inch rigid foam board to the wall with Liquid Nails construction

adhesive. I used boards to hold the foam in place while the glue

set. So

I decided to add 4 inches of rigid foam insulation to the exterior of

the wall for an insulation rating of about R24. First I dug down

about 8 to 12 inches and 5-6 inches away from the wall. Then

I attached 2 inch rigid foam board to the wall with Liquid Nails construction

adhesive. I used boards to hold the foam in place while the glue

set.

I had pre-cut the top edge of the foam to 15 degrees on my table saw for

a drip slope for the wood strip that will cover the top edge. I

also taped all the seams with aluminum tape to form a complete seal.

The second layer of foam was adhered with special foam adhesive because

Liquid Nails will not glue 2 non-porous surfaces together. |

Finally

after taping all the seams I glued on a layer of 1/4" fiberglass

reinforced cement sheathing

using Liquid Nails again. Once again I used boards to hold the

panels while the glue dried since it tended to slide down. The foam and boards all drop below

grade as far as I could practically dig which was 8 to 12 inches.

Here in Maine the frost level goes down about 36 inches. If I were

building new construction I would have wrapped the entire foundation in

foam insulation. Finally

after taping all the seams I glued on a layer of 1/4" fiberglass

reinforced cement sheathing

using Liquid Nails again. Once again I used boards to hold the

panels while the glue dried since it tended to slide down. The foam and boards all drop below

grade as far as I could practically dig which was 8 to 12 inches.

Here in Maine the frost level goes down about 36 inches. If I were

building new construction I would have wrapped the entire foundation in

foam insulation.

Note: I ran out of 2" blue foam, and had to run out and get more from a

different store where they only carry Owens Corning foam board which is

pink. It's basically the same material and R-value. |

To

protect the exposed edges I used 1X6" lumber that I ripped to 15 degrees

along the back edge of the top board. I used pre-primed lumber and

painted all sides with one coat of finish paint before attaching it to

the wall. I beaded the edge of the wood with dark colored latex

caulk before screwing the board to the wall. I used a pocket hole

jig to drive the screws in at a very shallow angle so that they would go

right into the wood along the top of the concrete. The pocket

holes were then filled with caulk. To

protect the exposed edges I used 1X6" lumber that I ripped to 15 degrees

along the back edge of the top board. I used pre-primed lumber and

painted all sides with one coat of finish paint before attaching it to

the wall. I beaded the edge of the wood with dark colored latex

caulk before screwing the board to the wall. I used a pocket hole

jig to drive the screws in at a very shallow angle so that they would go

right into the wood along the top of the concrete. The pocket

holes were then filled with caulk.

Finally I caulked all the seams with dark colored caulk and painted 2

more coats of good quality latex exterior paint. The finished

project blends in almost seamlessly. I am hoping that my wife's

legs will stay warmer now that the concrete wall will remain warmer this

winter!

Next year I plan to dig out from the wall and bury 2" foam 2 feet out

from the wall. The ground temperature remains at 45F year round

below the frost level which can be as low as 36" here in Maine. Trapping

that heat below insulation will help to keep the frost wall warmer below

grade. A building expert explained to me that the horizontal foam adds

an equivalent depth to the wall insulation. So by putting 1 foot against

the wall, and 2 feet out from the wall I could achieve the equivalent of

insulating 3 feet deep down the wall. I already did this on my

workshop, and hope to

document the improved insulation value later in the winter.

|

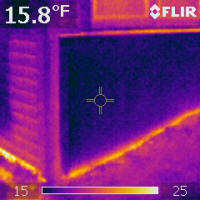

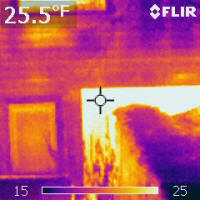

December 2008 follow

up:

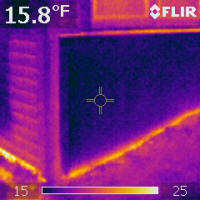

I borrowed a thermal camera that reads the surface temperature of things

as colors ranging from cool (blues) to warm (yellow). I went

out at night to document the new wall when it was 20F to ensure that

solar irradiance would not affect the reading and returned in the

morning to get the daylight view.

Note the temperature color scale at the bottom, and the cross hair that

is the point where the temperature reading is taken.

What is striking is that the exterior of the insulated wall is actually

below ambient at 15.8F, and that there is heat leaking out the bottom of

the wall which is insulated below grade to over 8".

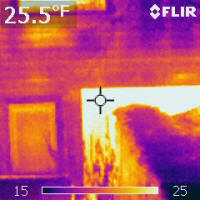

While the un-insulated concrete is at 25.5F - about 5 degrees warmer

than ambient, the insulated wall is almost 10F colder. This

implies that the insulated concrete on the inside of the wall will also

be 10F warmer. The basement was not heated so the interior

temperature was about 50F. It it were heated to the usual 75F that

my wife requires for processing the dyes in her clothing I imagine the

wall would be much hotter. Talk about a heat loss! Concrete

has an R value of about 0.01 per inch or R1 per 10 inches! So next spring I will be going around

the rest of the exposed foundation on the north side of the house and adding 4" of insulation all the

way up to the rim joist.

|

December 2009

Insulating the north wall:

The north wall of our basement has over 100 square feet of exposed

concrete wall and I decided to tackle this section next. Here's a shot

of the bare concrete wall with materials at hand. The inside of

the basement concrete wall is framed with 2X4s and filled with

fiberglass which has an R value of about 13.

We began at the top right by installing the first 2" sheet using Liquid

Nails and holding it down while the glue set. This foam board has

an R value of about 6 per inch, so 2 layers adds R24 to the wall. Then we added more

panels to complete the first 2" thick layer, at which point I sealed all

the joints with aluminum tape. We did this part of the work in

warm fall weather and finished the paneling after our first December

snow.

After installing the 2nd layer using special blue foam adhesive for the

foam-to-foam bond, I

installed wood trim around the top and exposed side. I primed and

painted all surfaces before installation, then caulked all the edges

after they were up. A final coat of paint covered the caulked seams.

Then I cut and glued on the primed T-111 siding to cover the foam.

I used Liquid Nails for this layer and propped it all up while it dried

and set. Then I went in with a can of Great Stuff and filled the

gaps around the edges to seal it all up. This was covered with

more caulk.

I have gone around the basement after the installation with a

laser infrared thermometer and found that the interior surface of the

exposed concrete wall averages about 10F colder than the inside ambient

air temperature while the outside temperature was 16.8F. Given that concrete has an R-value of about 1,

this is a huge improvement. The concrete would have been much

colder prior to installing the 4" of foam that totals about R24.

The temperatures have dipped below 10F just after the paneling went up

and we are already noticing that the basement stays warmer over night.

|

|

|

|

Interior drywall temperature

51.6F |

Interior concrete wall

41F |

Exterior T-111

16.8F |

|

See also:

August 2008: Insulating exposed frost walls of my solar heated workshop

and

December 2008: Insulating door and window framing

and

A thermal study of our buildings

|

|

back to my

Sustainable Living page |